Product Description

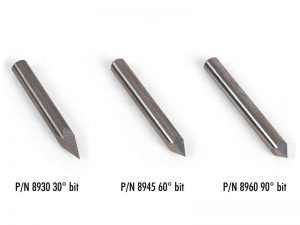

In most machining conditions it is not necessary to achieve tool speeds faster than the 10,000 RPM that can be produced with the standard DC motor spindle with optional high-speed pulley set. However, for engraving and other applications where extremely small, pointed tools are used, higher speeds are required for good finishes and acceptable feed rates. This spindle is capable of speeds up to 54,000 RPM and will hold 1/8″ diameter cutting tools in its collet spindle. Allowable spindle runout is specified by the manufacturer to be 0.0011″ (0.03 mm). Three carbide tools with various cutter-face angles are provided with your engraving head along with 7 grinding tips.

Click on the image for a larger view.

The high-speed spindle fits over the same mounting post on the mill saddle as the regular motorized headstock. An alignment key is provided for operation in the straight up and down position. The head can be angled by loosening the set screw that secures it to the mounting post, removing the spindle headstock, removing the alignment key from its slot and then replacing the spindle. The spindle can now be rotated to any position and held there by tightening the set screw against the mounting post.

The air spindle inserts through the longitudinal hole in the spindle body and is secured by tightening a single socket head screw. Speed is adjusted by rotating the chrome knurled ring near the top of the air spindle body.

Click on the images for a larger view.

PRECAUTION!

A carbide tool is being rotated at extremely high speeds. Should it shatter, pieces are flung outward at high speed. While eye protection is always recommended for any machining operation, good eye protection is absolutely imperative when using high-speed tools like this.