Product Description

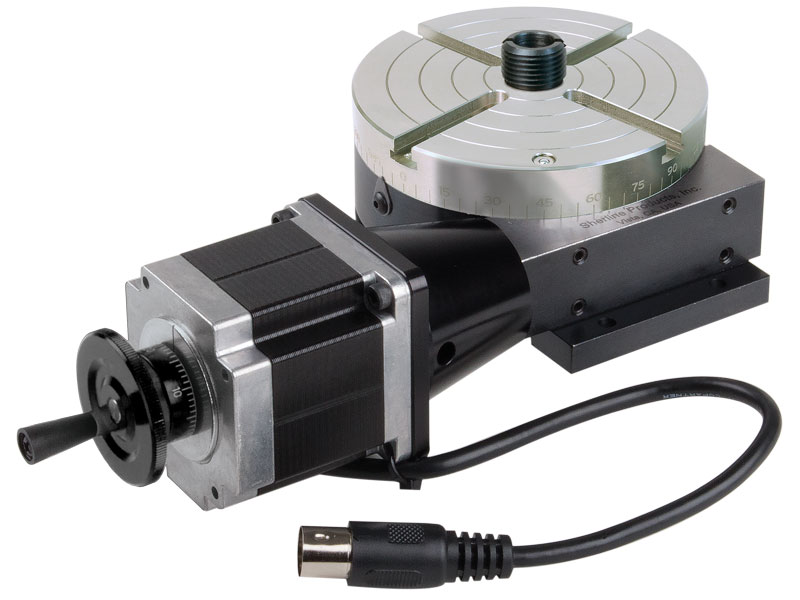

About the CNC Rotary Table with 15/32″ Through Hole

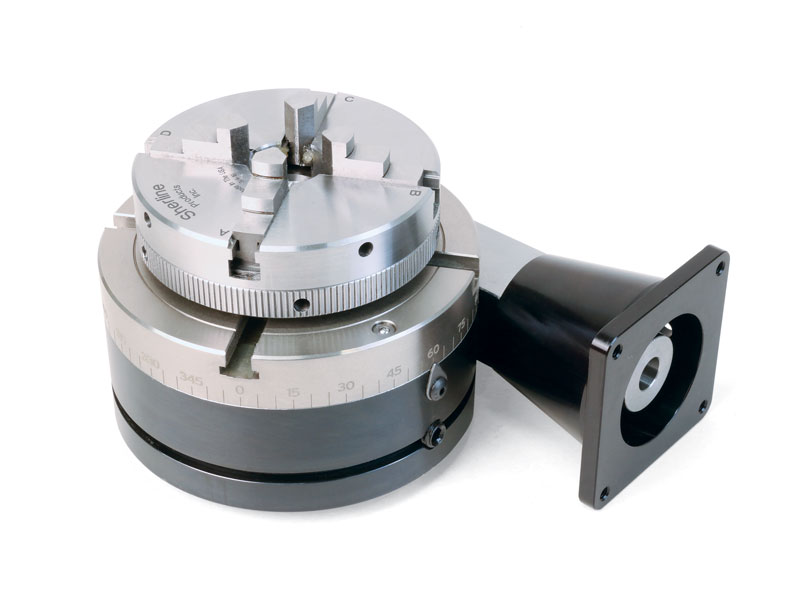

This is a modification of our 4″ CNC Rotary Table with Stepper Motor. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through hole to which you could mount our chucks.

This version of the Sherline rotary table has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

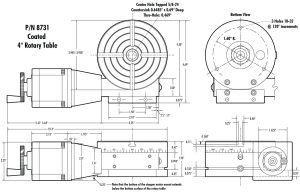

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel or stepper motor. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

- The through hole on this rotary table is 15/32″ (.469″)

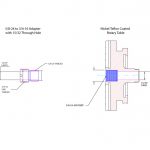

- The chuck adapter has a 3/4-16 thread for the chuck and a 5/8-24 thread for the rotary table

- There is a .6485″ c’bore at the entrance of the 5/8-24 thread which is used to locate the adapter concentric to the rotary table (See Figure 1 below)

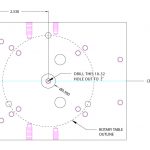

NOTE: In order to use this rotary table with our Tilting Angle Table (P/N 3750) you will need to drill out the 10-32 center hole to 1/2″ diameter. This will allow the maximum diameter of stock to feed through the rotary table (See Figure 2 below).

- Figure 1: Chuck adapter and rotary table through hole

- Figure 2: Rotary table layout

Click on images for a larger view.

Using the rotary table with the limit switches on the TAT

NOTE: For instructions on using the rotary table with the limit switches on the TAT, click on the Instructions tab above and download the PDF MASSO Rotary Table Limit Switch Interference on the Tilting Angle Table.