Product Description

Shortly after Sherline purchased a new engraving laser from Jimani we decided to manufacture our own laser engraving tooling plate. Jimani was already using our rotary table, and since we make our own X/Y tables, we believed that we could build a custom X/Y table with a tooling plate that would enhance the operation of the laser while adding ease and versatility to set-ups.

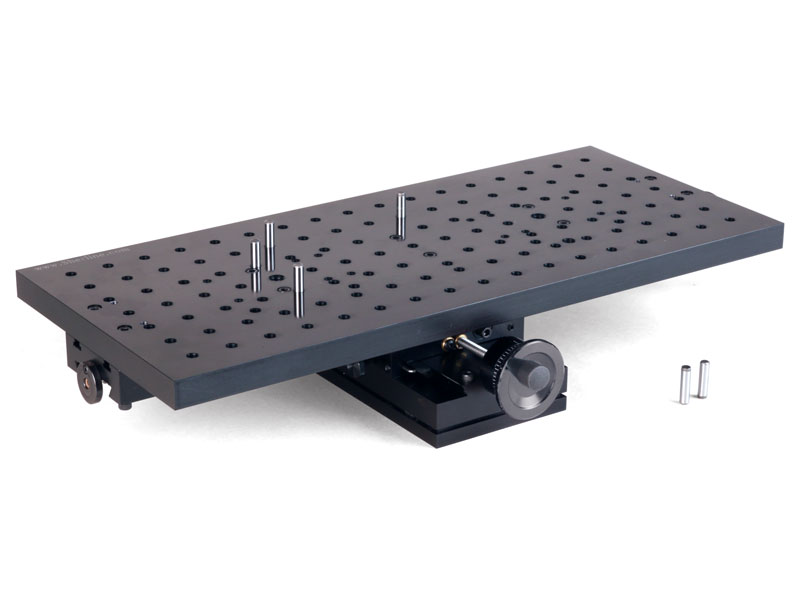

The tooling plate is 8″ x 18″ x ¾” black anodized 6061 aluminum.

This tooling plate was designed to mount on our 18″ Industrial X/Y Slide. The slide has 5″ of Y-axis travel and 13.6″ of X-axis travel. Handwheels are calibrated in .001″ increments for the inch slide and in .01mm increments for metric.

We at Sherline Products believe that our 8″ x 18″ laser engraving tooling plate will be a great addition to any engraving laser. Custom tooling plate hole patterns can be quoted upon request.

About the XY Slide w/18″ Table

The 2-axis XY machine slide has an 18″ table with plain handwheels.

Travel: X=13.38″ (340 mm), Y=4″ (102 mm)

For more details on the 2-axis machine slides with exploded views, CLICK HERE.

Some of the Features of the Tooling Plate

- (115 Green) Dual purpose ¼” holes, on 1″ centers. These holes are threaded ¼-20 on the bottom and reamed to ¼” on the top. This allows each hole to be used as a “part locating” hole when you insert a ¼” dowel pin. Each hole can also be used as a clamping hole using the ¼-20 thread.

- In addition to the ¼-20 holes, the plate also has (16 Red) 10-32 holes which are positioned to mount our Sherline rotary table and tilting angle table.

- There are (5 Black) ¼” through holes for locating the tooling plate square to the table.

- There is one (Purple) 5/16″ oiler access hole so you can fill the mill saddle oiler without removing the tooling plate.

- There are (10 Blue) T-nut mounting holes to assemble the plate to our mill table.

See diagram below for hole location and description.