Product Description

About the Sherline Stepper Motor Mounting Kit

The P/N 6500 kit includes the items you need to mount a stepper motor to drive any Sherline standard or industrial headstock spindle that accepts a motor mounting bracket.

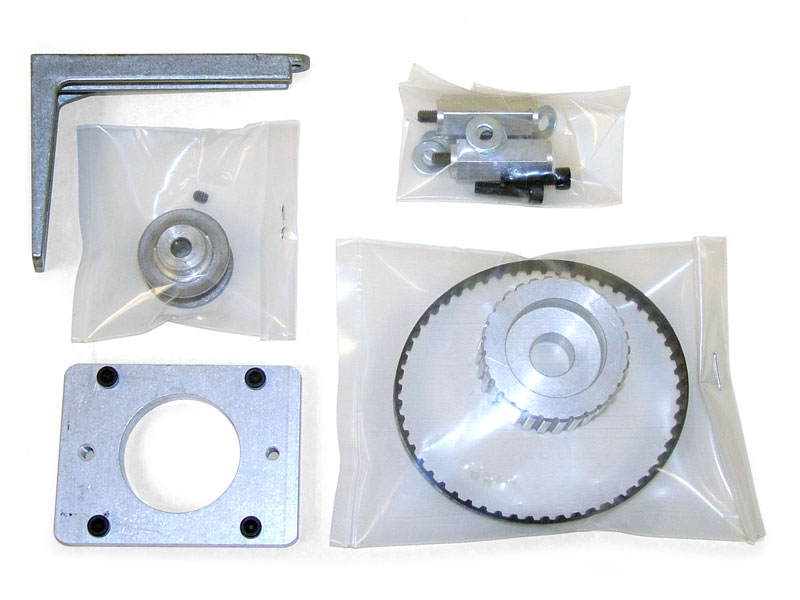

Included in the kit

The kit includes a custom bracket that supports the motor and the standoffs that attach to the mounting bracket. Also included are the standoffs, motor mounting bracket, 15-tooth motor pulley, 30-tooth spindle pulley, toothed drive belt and mounting hardware. Not included are the headstock and stepper motor (P/N 67127), which must be purchased separately. (A 10-tooth drive pulley is also available for special order for a slower 3:1 drive ratio instead of the standard 2:1 ratio. Call for details.)

Delete credit for DC spindle motor when ordering a complete lathe or mill

If you wish to order a Sherline lathe or mill that will be driven by this stepper motor kit rather than the standard DC motor, you can request that we delete the DC motor and speed control. The delete credit is currently $141.75 off the list price of the lathe or mill.

Installing the stepper motor

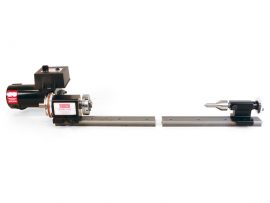

The conventional installation and an alternate space-saving alternative are shown below. If using the alternative method, flats must be ground on the spindle shaft to accommodate the pulley set screws. If this is not done, the galling of the spindle shaft caused by the set screw points can make the pulley difficult or impossible to remove from the shaft.

The first photo (Figure1) below shows the conventional configuration with the timing belt pulley replacing the standard 2-position V-belt pulley. This gives the most support for the drive belt. Although not originally designed for it, the motor can also be installed in the other direction as shown in the right-hand photo (Figure 2) if space requires. (The standard two-position pulley has been retained here in order to cover the bearings and preload nut.) Additional flats should be ground on the spindle shaft to accommodate the timing belt pulley set screws. The headstocks and stepper motors shown below are NOT included with the kit. (Click on the photos to view a larger image.)

The photos below show different stepper motor setups with a standard headstock with a 3/4-16 external thread and #1 Morse internal taper (Figures 1 & 2) and a 3C Collet headstock (Figures 3 & 4). Click on an image to view the photos in the gallery.

- 3/4-16 Standard Headstock Figure 1

- 3/4-16 Standard Headstock Figure 2

- 3C Collet Headstock Figure 3

- 3C Collet Headstock Figure 4

We have had customers who want to use the stepper motor (on the headstock) as a dual purpose motor. They want to use it to index the headstock to do machine work (mill flats, or cut out inlay areas on a pool cue). They also want to use it as a drive motor to turn stock (to replace the DC motor).

NOTE: Stepper Motor RPM Range

Max RPM = 225

Min RPM = 6 – 10