Product Description

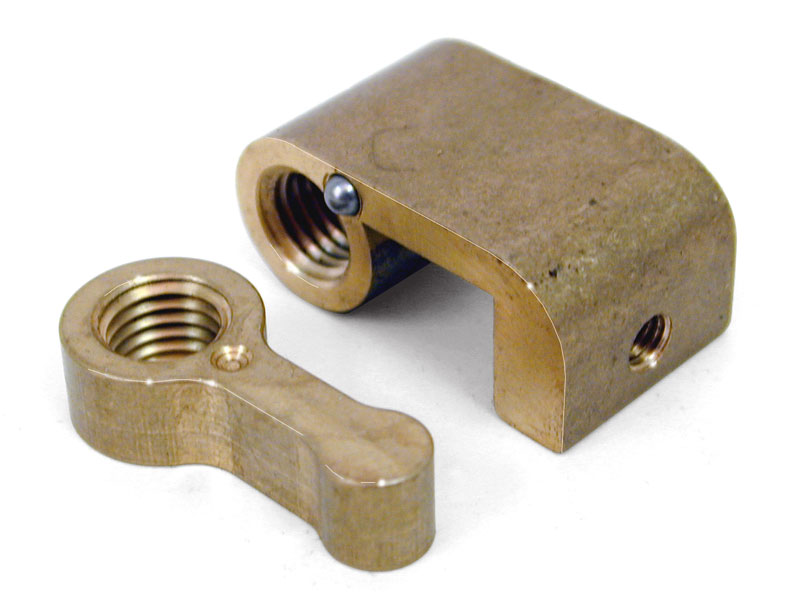

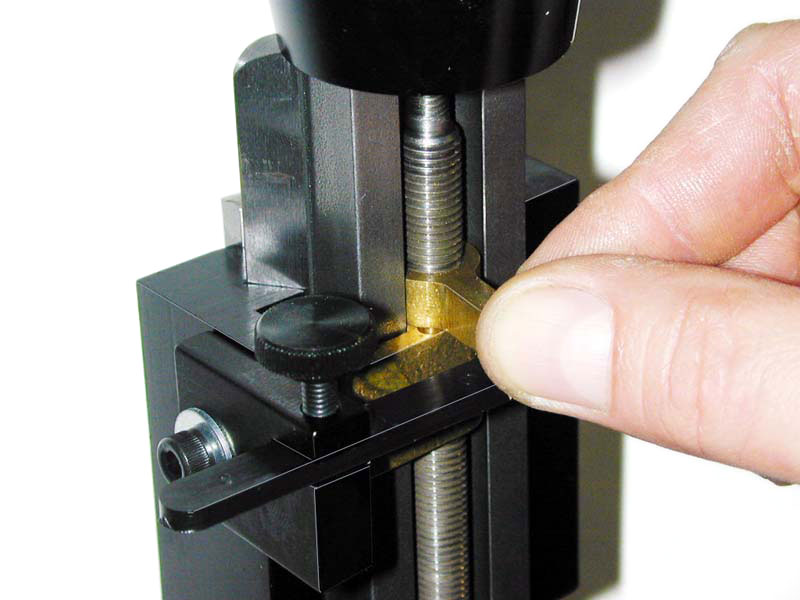

Sherline mills produced before 1999 used a nylon friction lock that was tightened using a socket head screw. It squeezed against the back side of the mill column gib and dovetail. With the introduction of the Model 2000 mill in late 1998, we changed the way the mill saddle was locked. The new system utilizes a brass lever on the leadscrew that locks against the top of the saddle nut. This provides a more secure lock that requires no tool to tighten. Older machines can be upgraded to the new system with the addition of this new locking lever and a new saddle nut that has a spring-loaded ball to keep the lever from self-locking when the leadscrew is turned.

If you are replacing a worn out saddle nut on an older mill, this new system will upgrade the function of your machine at the same time. Even if your saddle nut is not worn out, you might want to consider adding this feature to make locking the saddle easier and more positive.