About the Rotary Table Chuck Lock

The original design for this accessory was given to us by one of our customers, John Ferguson.

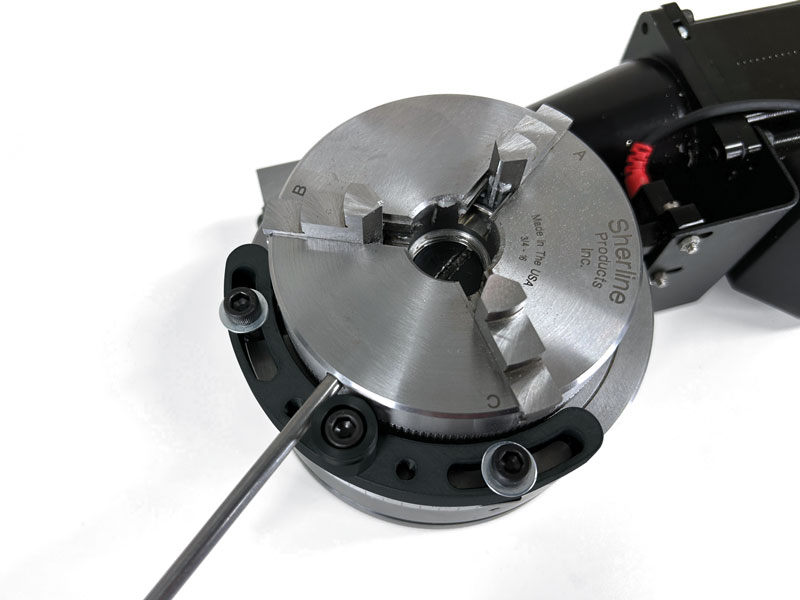

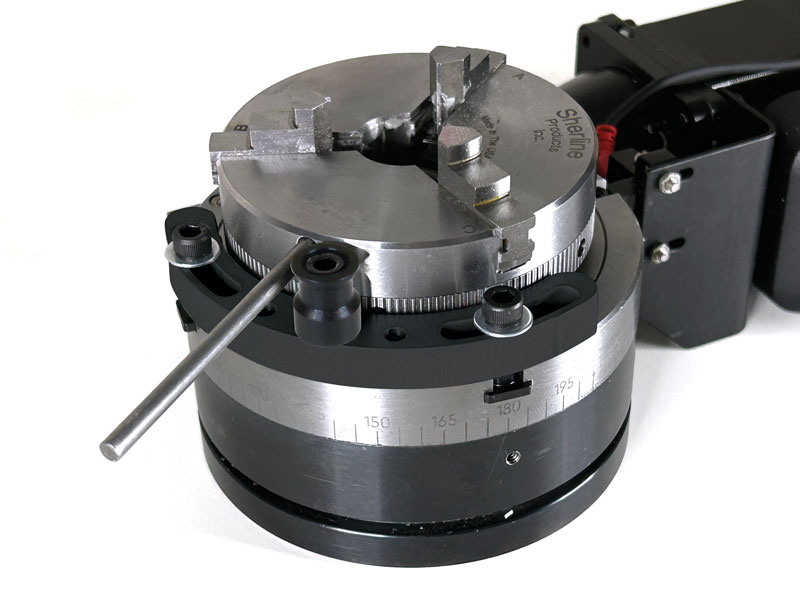

This accessory locks the chuck in place when you “thread mount” the chuck to our rotary table. The chuck lock prevents the chuck from unthreading itself during machining operations.

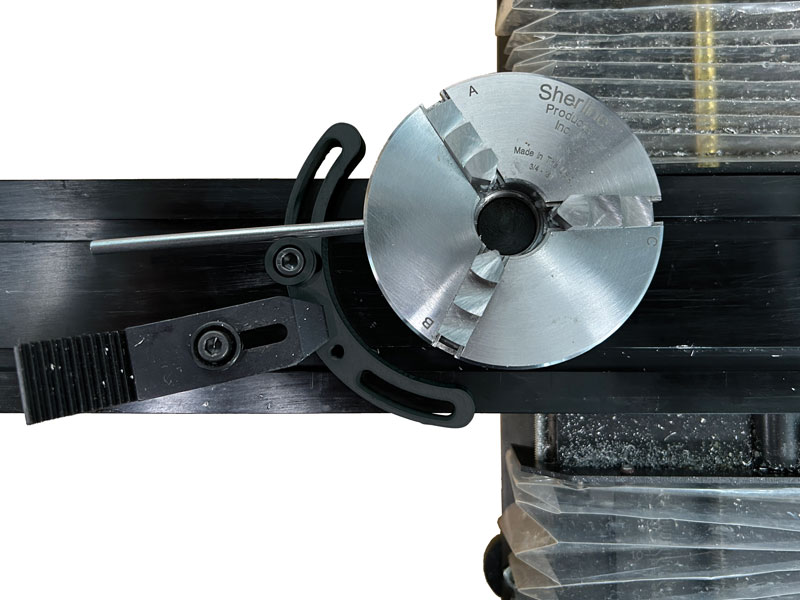

The rotary table chuck lock is designed primarily to work on our rotary table, but it can also be mounted directly to our mill tables when using our 3- or 4-jaw self-centering chucks (2.5″ and 3.1″ diameters), along with the Chuck to T-slot Adapter (P/N 1187) to secure the chuck to the T-slot on the table.

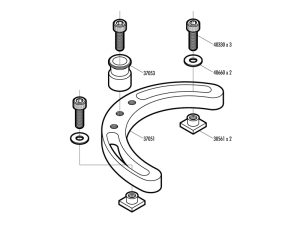

Mounting the Chuck Lock

Rotary Table: The rotary table has four T-slots. The self-centering chucks have three or four Tommy bar holes. The chuck lock can be rotated 82 degrees. The chuck lock body also has three different mounting hole locations for the “stop pin.” This makes it easy to find t-slots that will allow the chuck clamp (and stop pin) to be mounted near one of the Tommy bar holes in the chuck. Insert the Tommy bar into the chuck. Rotate the chuck lock body until the “stop pin” is forced against the side of the Tommy bar. Then lock down the chuck lock to the rotary table.

Mill Table: This same procedure is used when mounting a chuck to our mill table. Secure the chuck lock to the table either by using the T-slots in the table, or using a clamp to secure the chuck lock in place.

NOTE: See the above photos for mounting references.