Product Description

About the Ceramic Insert Tool Holder

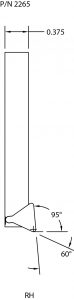

Tough materials like tool steel require special tools to cut them. This triangular ceramic insert is held tilted down slightly on the tool holder creating a negative rake. This angle provides tool clearance on the sides of the flat sided insert, meaning you get six separate cutting points from one insert. The 3/8″ shank is held in Sherline’s P/N 7600 tool post (not included). A hold-down clamp, screw, and a 3/32″ hex key are included with the holder and insert. Additional inserts are available as P/N 22659.

About Ceramic Cutters

Ceramic inserts are a relatively new tool in the machinist’s arsenal. Though brittle, when used properly they have the ability to cut hardened steel and to do so at higher speeds. This insert has a relatively large nose radius which will provide a very nice finish when profiling. If you ever need to turn down the shank of an end mill, for example, this is the only way to go. This would be nearly impossible with high-speed steel tools and very difficult even with carbide tools. Though slightly more expensive, if a cutting edge becomes dull or chipped, the insert can be removed and rotated 120° to expose a new cutting surface. Another 120° and you have a third cutting surface. Then you can flip the insert over and you have three more surfaces before you need to replace the insert. Compared to carbide inserts that have either two (positive rake) or four (negative rake) surfaces this six-sided shape makes them pretty economical to use despite the higher initial price.

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily re-sharpened and can be ground into “form” tools for special jobs. However, inserted tip tools can be lifesavers for some jobs. This is why they find a lot of use in the modern professional machine shop.

CAUTION: Chips coming off the ceramic cutter can be RED HOT! Use extreme caution. Ceramic and carbide inserts can also shatter. For these reasons, proper protective eyewear and clothing are especially important when using these tools.

Some materials like tool steel tend to build up a long, thin chip that wraps around the spinning part like steel wool. Use a chip brush or stop occasionally to remove this material often. Note that red hot chips can cause this “bird’s nest” clump of material to burn. Clean up often to keep the pile of chips to a minimum near the cutter.