Product Description

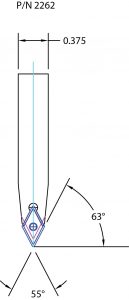

This holder is not offset to either side, and it comes with a 55° carbide insert, hold-down screw and special Torx key. The 3/8″ square shank is held in a 3/8″ tool post. The straight tip tool can be used as a general turning tool, cutting either right or left. The tip of the cutting tool is .375″ from the bottom of the holder, which is the industry standard. The holders are made from case hardened steel with a black oxide finish.

Though relatively expensive, if a cutting edge becomes dull or chipped, the insert can be removed and rotated 180° to expose two new cutting surfaces, providing, in effect, two tools for the price of one.

About the Cutter Inserts

The primary method of cutting metal on miniature machine tools is usually with high-speed steel tools as they are inexpensive, easily resharpened and can be ground into “form” tools for special jobs. However, inserted tip tools can be lifesavers for some jobs. This is why they find a lot of use in the modern professional machine shop.

CAUTION: Chips coming off the carbide inserts can be very HOT! Use extreme caution. Carbide inserts can also shatter. For these reasons, proper protective eyewear and clothing are especially important when using these tools.

Some materials like tool steel tend to build up a long, thin chip that wraps around the spinning part like steel wool. Use a chip brush or stop occasionally to remove this material often. Note that red hot chips can cause this “bird’s nest” clump of material to burn. Clean up often to keep the pile of chips to a minimum near the cutter.