Product Description

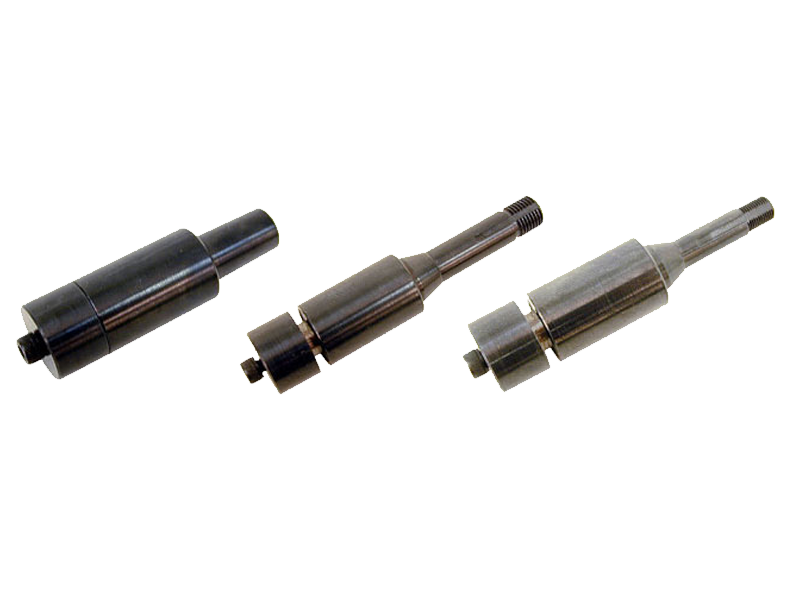

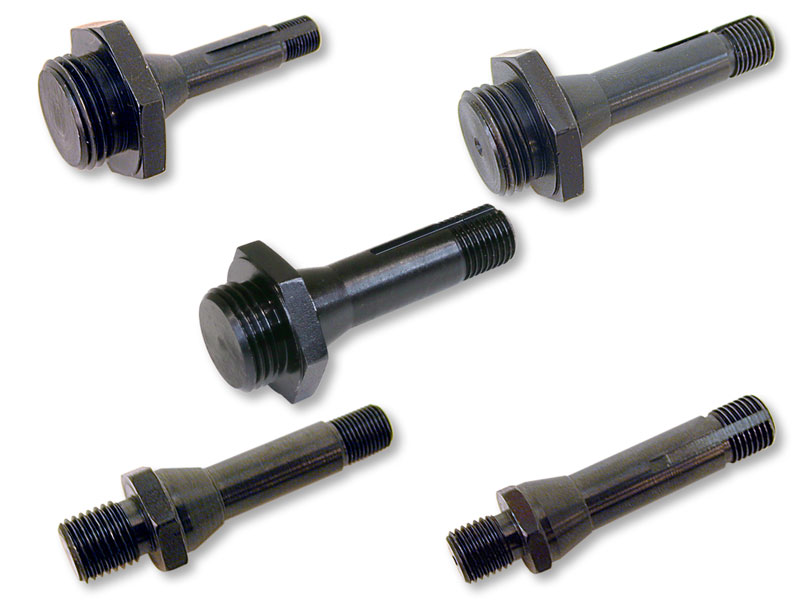

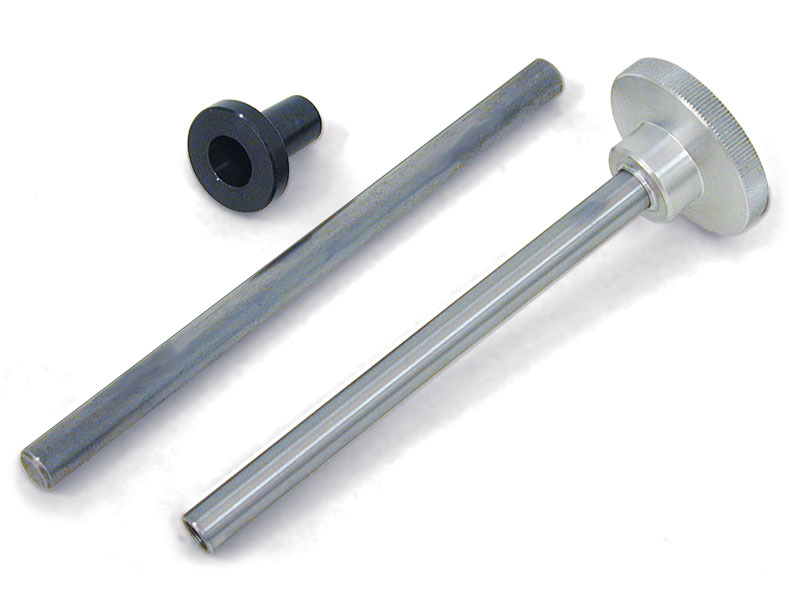

About the Clockmaker’s Gear-Cutting Arbors

Clockmaker’s gear-cutting arbors are primarily designed to be used on watchmaker’s lathes that accept 8.0 mm or 10.0 mm “D” collets. The P/N 2094 Gearcutting Arbor, with its #1 Morse taper, is designed for use on your Sherline Lathe. With the use of an 8 mm Adapter, the 8mm arbor can also be used on Sherline lathes, although the normal system for mounting chucks is recommended.

Something New for Our Clock and Watchmakers

One of our Sherline customers, David Bishop, introduced us to some software for making gears. Because gear cutters for clock gears are expensive and hard to find, we are sharing this information with any of our customers who are interested. This software allows you to design your gear by entering all of your gear dimensions and information. Then it will generate a G-code program so you can cut your gears on a CNC mill. David uses one of our Sherline CNC mills to cut his gears. He uses superglue to mount his brass stock onto a piece of aluminum. Then he cuts his gears with a .030″ (.7 mm or .8 mm) diameter carbide end mill at a very slow feed rate of about (0.2 mm/min). He then heats the gear to break the bond of the superglue to free the gear from the aluminum block. The gears that David has made have a finished quality right off of our machine.

The Gear Wheel Designer program was created by Graham Baxter and can be purchased from Delph Electronics, via Steve Lunn, at this site (DelphUSA Gear Wheel Designer).