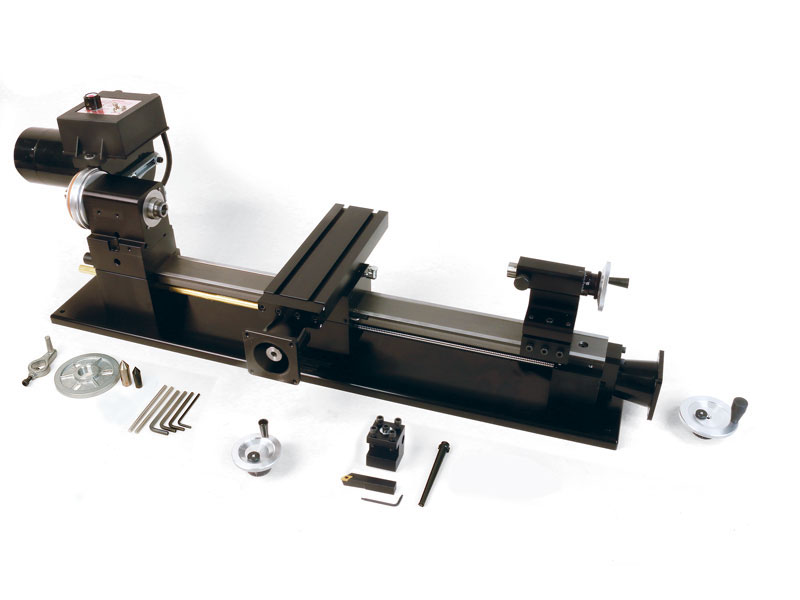

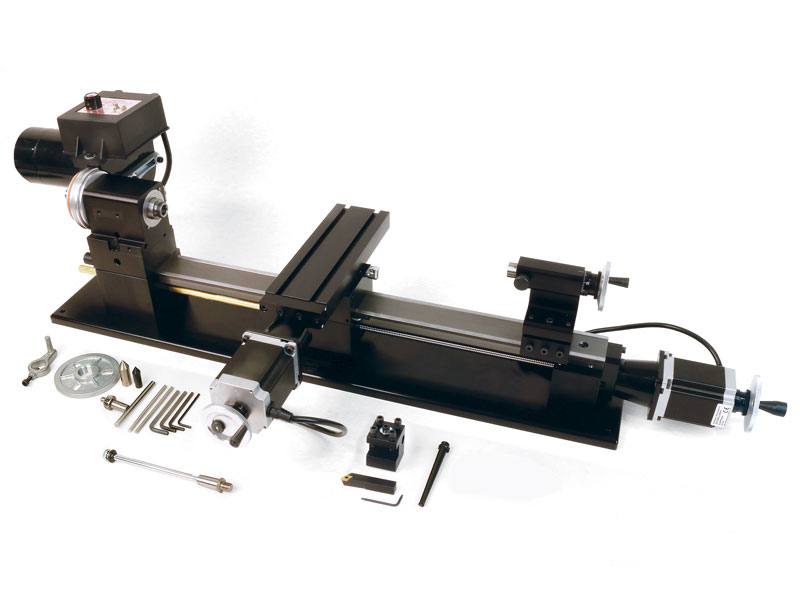

The ball screw lathe design is a reimagined version of our popular 17″ 4400-series lathe. The lathe has a new solid aluminum base, which creates a very rigid assembly, a beefed-up saddle to accommodate the ball screws, a larger 8″ crosslide, and #23 NEMA frame stepper-motor mounts with high-torque couplings.

Ball Leadscrew Specifications

- Rolled Ball Screw with BSH Nut

- 10mm Diameter, 2mm Lead

- C7 Accuracy*, P1 Preload

*C7 accuracy has a linear tolerance of 50 micrometers / 300mm or .002″ / 12.0″.

The ball screws are only available in metric, so the numeric graduations on the handwheel dials are 2mm per revolution and .02mm per line.

Connecting your CNC-Ready Lathe to a Controller

Once you have the machine, you will need to attach stepper motors, a CNC driver, and a CNC controller. Sherline offers the following options to connect your ball screw lathe to a CNC controller:

- Stepper motors–High-torque (P/N 67126, recommended) or standard (P/N 67127)

- CNC controllers w/4-axis CNC Driver box–MASSO (P/N 8780) or Linux CNC computer (P/N 8761)*

*NOTE: A mouse and keyboard are included with the Linux PC. You must provide a USB dongle and wireless keyboard and mouse set with the MASSO controller.

Ordering options:

Use the selections in the drop-down menus above to configure your machine. See the Options tab above for more specifications on each option and accessory packages.

- A powerful 90V DC motor with electronic speed controller*

- Standard headstock: #1 Morse taper with 3/4 x 16 external spindle thread (Option to upgrade headstock above)

- The base is 28″ x 5″ x 1/2″ solid 6061 aluminum plate, and the headstock and tailstock mounts are solid, machined 6061 aluminum

- The lathe saddle is hard anodized for long wear, and internal oiling ports are incorporated to keep the lathe bed dovetail areas lubricated

- 2.75″ (70 mm) x 8.0″ (203 mm) crosslide

- 24″ (711 mm) steel bed that has 17″ (431 mm) between centers

- 2.5″ (63 mm) resettable “zero” handwheel for the leadscrew, one 2″ (51 mm) resettable “zero” handwheel for the crosslide feed screw, and a 2″ (51mm) resettable “zero” handwheel on the tailstock. Each handwheel has laser engraved aluminum handwheel collars*

- A 3/8″ Insert Holder Tool Post (P/N 7600) with a 55° RH Carbide Tool Holder (P/N 2256)

- Pulleys, drive belt, faceplate, lathe dog, two dead centers, three hexagonal keys, eight-foot three-wire power cord, and instruction manual

- Optional limit switches***

* Not included with a lathe without motor and speed control.

**CNC-ready machines cannot be operated manually unless double-shaft stepper motors are installed.

***The limit switches were designed to work with our Sherline/MASSO G2 CNC Controller, but you can connect them to any controller that is configured to work with our limit switches, such as Mach 3, Mach 4, etc. See related products below for limit switch product page.

The MASSO G3 CNC controller, power supply, stepper motors, cable system and optical encoder are sold as a part of our Accu-Pro line of machines and are not available for purchase separately or as an upgrade option to existing machines.