Product Description

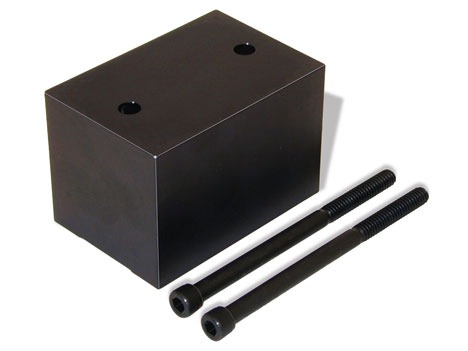

A riser or spacer block is used to increase the height of the mill column, either to clear a larger work piece or to accommodate a tall setup like a vise on top of a rotary table on top of a tilting angle table. This block raises the column an additional 2.0″. To install it, the milling column is removed from mill base, the two-inch extension block is placed beneath the column base and the new, longer bolts are brought up from below the mill base, through the block and tightened into the mill column block. It is then aligned and used just like before. If travel all the way down to the table surface is required, the block can be removed and the mill column return to stock height.

Another Way to Extend the Z-axis Travel

An alternative to the riser block is to use a longer column. Sherline now offers a 15″ mill column that can be installed in place of the standard 11″ column. This allows the cutter to be brought down to the table as is possible with the standard column, but it adds an additional 4″ of travel to the top end of the column. A user would purchase the 15″ extended column and the 15″ leadscrew. These components would replace the standard column bed and leadscrew and all other parts of the mill would be retained. Call for details or see these part numbers in the Replacement Parts Price List.