Product Description

About the Sherline Industrial linear machine slide with programmable CNC controller

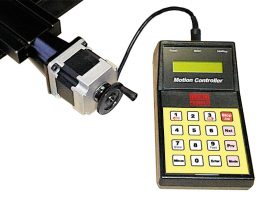

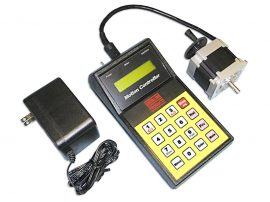

Sherline offers single-axis controllers to drive the stepper motor on any individual axis of the lathe or mill. No separate computers or drivers are needed. The keypad/control unit has its own computer chip built-in. It is all ready for you to use the keypad to drive the stepper motor directly or to enter simple program commands to do sequenced operations. No knowledge of G-code is required. Parameters that can be entered are direction, distance to travel, feed rate, and whether or not the program pauses to wait for another command or proceeds to the next step. Up to 40 programmed steps of four parameters each can be entered into either of two separate user-settable programs. Controllers can be interconnected with a cable to signal each other to act in sequence. They can also be connected to other CNC system controllers to communicate with “sense” and “acknowledge” signals so that they perform their preprogrammed functions at the proper time during a CNC program sequence.

The stepper motor mounts feature dual ball bearings with a preload nut to eliminate endplay. A dampened coupling connects the 1/4″ diameter shaft of the stepper motor to the leadscrew. The use of a dual-shaft stepper motor allows manual cranking by means of the supplied handwheel as an alternative to computer-controlled movement. The controller uses micro-stepping to provide accurate, smooth travel.

Mounting Provisions

FROM THE BOTTOM—Four 1/4-20 holes are provided in the base’s bottom on 2-inch centers for mounting.

FROM THE TOP—If access is not available from the bottom, the slide can be mounted from the top using the four angle clamps provided. They slide into the groove around the perimeter of the base, and holes are drilled in the mounting surface and tapped to accept the 10-32 socket head cap screws provided. Use all four clamps for the most secure mount.

- Single-axis slide, available with 8″, 13″, or 18″ table

- Linear Controller w/Keypad

- Power Supply

- #23 Frame Size Stepper Motor

- 1-5/8″ Handwheel graduated in .001″ increments on inch slides and in .01 mm increments on metric slides.

- Cables

- Complete instructions

NOTE: The power supply included with this indexer (linear controller) is intended to operate only on 115/120 VAC, 60 Hz (38 W) current. For countries operating on 100, 220, or 240VAC and/or 50Hz a transformer will be required. As an alternative, this power supply outputs 24VDC, 1 Amp (1000 mA). If you can purchase an appropriate power supply that operates on local current and outputs 24VDC, 1A current, it could be used to power the unit instead of the one supplied. Sherline Products does not provide a 220V power supply or transformer.

Weight Capacity

Our slides’ weight capacity is about 10 lbs. depending on where the weight is located and how long the table is. On an 18″ table, you should not go more than 10 lbs. of weight at the end of the table (there is a leverage factor). If the weight is more centrally located (closer to the base), you can exceed the 10 lbs. limit.

Duty Cycle

Under heavy constant use, the dovetail area of the slide will start to show some wear on the anodize after one year (2080 hours). They are still fully functional at this point, but the anodized coating will begin to wear thin. The dovetail and the screw will last longer if you keep them lubricated with light oil*.

*NOTE: Do not use WD-40 as a lubricant on these slides. WD-40 will remove the anodized coating from these parts!